Nanotechnology can be very useful for processes and can collaborate with the practice of sustainable mining

Current scenario of nanotechnology in mining

When analyzing the current contribution of nanotechnology in mining, there are few examples of investments in research that focus on improving the processes that involve mining activity in itself.

Perhaps this is because mining is a well-established sector of the economy, which values incremental innovation, seeking, in most cases, lower process costs, given its status of commodity. This kind of vision goes against the current mentality of investments in research and development. In this case, the R&D process would need to bring an effective result, reaching the final objective, which is often related to the optimization and reduction of process costs.

The fact is that for this innovation process to be successful, it is necessary to overcome challenges that range from mindset changes in the mining industry to the optimization of R & D management. A better relationship between industry and university is essential.

Thus, many innovations related to nanotechnology in mining are still restricted to universities, they need investments to become a reality in the market. These innovations have great potential and show that the mining industry and nanotechnology can work together.

Graphite and graphene can contribute to the use of nanotechnology in mining

Graphene can be useful for energy storage technologies, contributing to the purpose of sustainable mining.

When we analyze the product of mining, it is possible to notice some changes in specific areas, such as mining graphite. Brazil has the third-largest global reserve of graphite, a strategic mineral. It has attracted attention because it is one of the largest volume inputs to be used in the anodes of lithium ion batteries. Due to limited natural resources, there is an urgent need to mitigate the dependency on technologies related to the production of lithium-ion batteries and supercapacitors.

Nanotechnology, in this case, makes it possible to add value to the mineral, through its conversion into a nanomaterial. In this way, it is possible to use less material, now optimized, to solve increasingly challenging problems, such as smaller and more powerful batteries. This is a concrete possibility of making a circular economy effective. The presence of a circular economy is important in the reality of Brazil and can contribute to the transformation of the current scenario.

The production of graphene, in addition to other nanocarbons possible to be obtained from natural graphite, is configured as a potential input for technologies related to energy storage such as batteries and supercapacitors. Thus, they serve the purpose of sustainable mining, promoting the use of less raw material, which represents an optimized solution for society.

For the future: possibilities of nanotechnology contribution in mining

Although not a reality, several pieces of researches related to nanotechnology in mining are developed at the university.

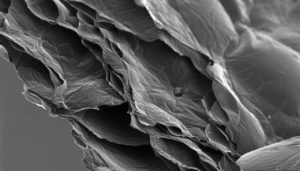

An example of these innovations is the use of graphene in barrier coating, on drills, and also for holes for a probe. These drilling processes can be time-consuming, especially when it comes to a deep hole. Drills are submitted to a lot of mechanical abrasion, heat, and increased pressure. Graphene protects these drills because it offers stability against impact, temperature, and active chemical species.

There are more benefits to using graphene. By using a small amount of this nanomaterial, it is possible to increase the lifespan and decrease the frequency of the drill’s replacement.

A method to isolate gold from raw sources, allowing extraction without the use of toxic chemicals, such as cyanide (used in a standard process) has also been the subject of some studies. Researchers mixed starch-derived alpha-cyclodextrin and a dissolved gold salt (KAuBr 4 ), which formed individual needles made up of thousands of bundles of nanometer supramolecular threads (1.3 nm in diameter). In each wire, the gold ion is held together in the middle of four bromine atoms, while the potassium ion is surrounded by six water molecules; these ions are sandwiched alternately by the alpha-cyclodextrin rings. The needle synthesis process is relatively quick and could be commercially viable.

Another area with potential is the area of lubricant additives. In mining, the use of heavy machinery requires effective and regular lubrication of its parts to prevent wear and degradation. Nanoparticles have been tested to improve lubricating properties. Due to their size, they easily pass through filtration systems and penetrate small spaces between the mechanical parts. In this way, these nanomaterials would act as “small rolls”, when the mechanical parts pass over them.

Technology that already is a reality

Nanofiltration and nanoflotation are used in mining to purify and extract lithium from heavy petroleum from wastewater. Nanofiltration is the separation process that uses membranes to separate heterogeneous solutions and solutes dissolved in water. In this case, the membrane is a selective barrier and has nanometer-sized pores. Nanoflotation is a mixture separation technique. It consists of the introduction of air bubbles (with nanometric diameters) to a heterogeneous suspension of particles. These particles adhere to the nanobubbles and form a foam that, after being removed from the mixture, allows the separation of the components. The mining company MGX, in Canada, has the technology that, in comparison to other processes, they perform the removal of contaminants from the oil and gas fields with superiority.

According to the company, “the technology allows water treatment at extremely high temperatures (up to 700 ° C), surpasses between 10 and 30 times the efficiency of existing ultrafiltration systems and offers numerous environmental benefits, including removal of contaminants, mineral recovery, reduced energy demand, smaller footprints, and lower capital costs ”. In this way, the company successfully concentrated lithium from the wastewater from the Sturgeon Lake oil field.

The Gübelin Gem Lab, in Switzerland, launched a method that uses nanotechnology to trace the origin of emeralds, called the Emerald Paternity Test. This new technology uses nanoparticles (with a diameter of about 100 nm) combined with DNA. This ‘mix’ is applied directly to the raw crystals in the mine. The nanoparticles resist the mining, cutting, and polishing processes, as they penetrate the mineral’s cracks. In the final jewel produced, the nanomaterial is preserved and allows the “paternity test” of the emerald, allowing confirmation of its origin. Tests made at the world’s largest emerald mine, Kagem, in Zambia, proved its efficiency.

Numerous other technologies have been developed with the use of nanomaterials. They are used to reduce the environmental impact in mining, to remove heavy metals present in the acid mine drainage process, and also to recover up to 100% of precious metals in raw minerals.

Perspectives for the future

Nanotechnology in mining can be even more useful. Investment is a fundamental part of the process. The lack of it is probably a major barrier for innovations to come out of university labs and to contribute effectively to this industry.

In Brazil, despite the negative impacts of dam breaks recently, the forecast is that the sector will receive, between 2020 and 2024, 18% more investment than expected for the previous period, from 2019 to 2023.

The Harvard Business Review’s information can be an extra incentive for investments by mining companies. The Harvard Business Review’s information says that investments in innovation are responsible for 38% of revenues and 61% of company profits. There is also the “Law of Good” (11.196/05), which creates tax incentives for legal entities that develop research and technological innovation. According to the MCTIC, until 2018 more than R $ 149 million were invested in nanotechnology through the use of the “Law of Good”.