Graphene’s been available on the Market for some years, and it’s production reaches several tons/year in many produces around the world. According to the website Statista1, leading companies in this market already have a market capitalization of over one billion US dollars.

We have products on the market containing graphene and there is an expectation and a lot of investment in the development of new nanoproducts containing the nanomaterial, for various applications. In other words, graphene is expected to be even more produced and applied.

However, other developments are related to this scenario when we think about the health and safety implications and ethical, legal and social aspects of this area of technology.

This post will address one of these aspects: monitoring the air of this nanoform, an activity that Nanos has expertise. This question “how to monitor graphene in the air?” was recurrent in our academic training. That is why we are sharing here some technical knowledge that permeates this type of work. At the end of this article, there is also an interview with Stat Peel, a partner of Nanos that also operates in this field.

Occupational Exposure Limits for Nanomaterials

Due to the complexity of nanomaterials in terms of size, surface area, charge, composition, reactivity, and other properties, it was not possible to establish an Occupational Exposure Limit – OEL based on health. OEL is a standard value below which most people exposed to it do not get sick or have discomfort caused by the physical, chemical or biological agent. However, as published by OSHA2, some organizations such as the National Institute for Occupational Safety and Health of the United States (NIOSH), the British Standard Institute, the Institute of the Professional Cooperative Society for Occupational Safety and Health of Germany (IFA) and the World Organization of Health3 suggested temporary OELs for nanomaterials such as carbon nanotubes, titanium dioxide, fibrous, granular, soluble nanomaterials and others. (In this publication we present a comparative table with some of the proposed values for carbon nanomaterials.)

Among the suggested limits, it is observed that there are variations in values due to the nature of their generation and therefore the OSHA recommendation is that employers minimize worker exposure as much as possible, using appropriate exposure control methods.

How to detect nanoparticles in air?

The analysis of exposure to the nanomaterial in the work environment is complex because the evaluation of its main properties involves the use of sophisticated techniques and equipment, with limitations.

For measurements of suspended nanoparticles, active or passive sampling methods are used. In the active, measurement methods can be online, where measurements are performed in real time, providing the concentration, number of particles, surface and mass concentrations, and characteristics related to the size or optical properties of nanoparticles in air. However, although these devices are able to analyze particles of different grain sizes, they do not distinguish their composition. Examples of these samplers are:

- optical particle counter (OPC);

- condensation particle counter (CPC);

- light scattering photometer for aerosols;

- carbon black monitor (BCM).

They can also be carried out by off-line quantitative analytical methods, where quantitative determination (by mass) and identification of the type of nanomaterial takes place, requiring long-term sampling through other equipment. The advantage would be the possibility of analyzing the air collectors filters to determine the composition and verify the presence of nanoparticles in the filter. However, when analyzing the filters, there is a risk of not detecting many particles that may have deposited in the pores. Examples of analyzes used are:

- gravimetric analysis;

- elementary analysis;

- high-performance liquid chromatography methods;

- Raman spectroscopy;

- X-ray diffraction.

On the other hand, in passive methods, there is the natural deposition of nanoparticles on different substrates (TEM grids, silica or carbon ribbons) in order to visualize their presence through an electron microscope. Despite identifying the nanoparticle, the method is expensive, time-consuming and the uncertainties related to the behavior of these particles in air would make it difficult to determine the ideal time for their deposition and sedimentation on these substrates4,5.

Appendix R14-4 of the “Guidance on information requirements and chemical safety assessment” of the ECHA (European Chemicals Agency) provides recommendations for estimating occupational exposure to nanomaterials, addressing considerations about the background of the concentration of nanomaterials from various sources in the environment. Particle size distribution measurements, metrics and measurement strategies, other equipment that can be used, and other considerations6.

Examples of equipment that can be used in strategies (active and passive) for monitoring nanoparticles in air

To analyze worker exposure to the nanomaterial in question, an occupational health and safety professional should access the resources available and try to combine sampling and analysis methods according to the characteristics of the nanomaterial, the workplace and the processes involved.

Monitoring graphene suspended in the air

As described above, there are several analytical methods that allows us to detect nanoparticles. Thus, the detection of a specific nanoform is based on its unique properties and characteristics. We know that the particulate material suspended in the air is formed by different materials and chemical compounds, thus, it is through the specificities of the nanoparticle that it is possible to distinguish it. Only in this way were we able to find this ‘needle in a haystack’.

With the graphene, there is no difference: it is through its properties that it is possible to detect it in the air and monitor its exposure. But, we also know that, in these terms, “graphene” is a generic word: there are several graphenes. Therefore, the monitoring of graphene in the air is not like the monitoring of a ‘conventional’ particulate material. The success in detecting it, and any other nanomaterial, is based on the knowledge of its specific properties, and it is from these that the specific monitoring system will be developed and structured for each ‘graphene’ that makes up the exposure scenario of the environment of work under study.

Nanos has expertise in this type of investigation6,7, and is also a partner of a Swiss company, Stat Peel, which, for eight years has been developing and marketing equipment for detecting nanomaterials suspended in the air, including nanocarbons such as graphene. To further enrich this article, we conducted an interview with the company’s CEO, Rudolf Bieri.

Interview with Rudolf Bieri, Stat Peel’s CEO

1. Tell us a little about Stat Peel and the motivations that guided the opening of the company 8 years ago.

Growing up in an industrial part of Switzerland I became familiar with the negative impact of occupational exposure early on. A local fiber cement plant used large amounts of asbestos with a devastating impact on workers and the community.

Working in the semiconductor equipment industry I realized that exposure monitoring airborne, toxic material is very challenging and easy to operate tools are not available. That’s when I decided to start Stat Peel to develop our monitoring system the Identifier.

2. How does Stat Peel monitoring device work? Based on which principle does Stat Peel equipment detect these nanomaterials?

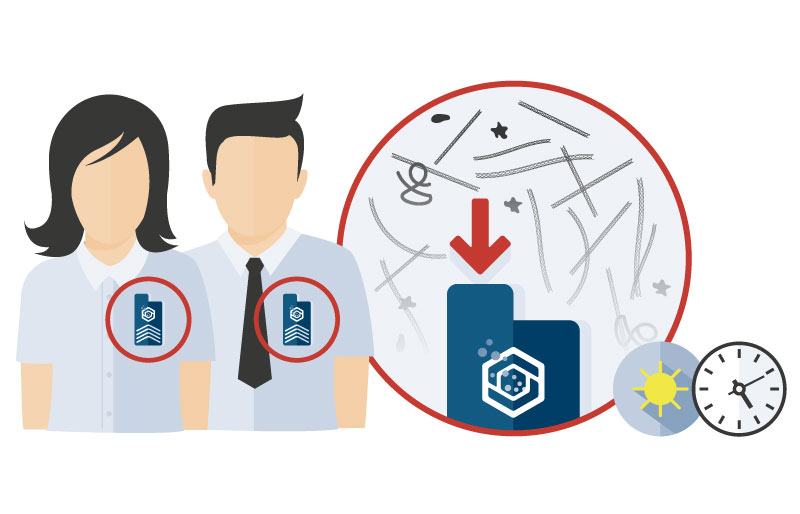

Our lightweight, dosimeter-like badge contains multiple sensors and uses a consumable filtration slide. During the course of the workday, a small amount of air is filtered. At the end of the work shift, the badge is inserted into a benchtop reader which removes the slide and inspects the collected particles automatically using Raman spectroscopy. Exposure data are stored and matched to individual employees. Comprehensive exposure reports are generated which can be used to show compliance with recommended exposure limits to government agencies, insurance companies or customers.

Stat Peel’s Identifier collects airborne particles during the work shift. The detection of the nanoparticle of interest occurs later by Raman spectroscopy

3.Does the type of sampling that is carried out follow any standards? Is there an obligation to carry out monitoring for any type of company / material?

In the countries we operate in there’s the General Duty Clause, which requires employers to provide their employees with a workplace free from recognized hazards likely to cause death or serious physical harm. This clause is the foundation for any monitoring activity even if there are no material specific exposure limits in place yet.

Country specific sampling rules can differ quit substantially, personal vs stationary sampling or the sampling duration, for example.

4. What type of nanomaterial do most of Stat Peel’s customers work with? In other words, for which type of nanoparticles is there more search for monitoring solutions?

Among the advanced material customers most work with carbonous materials like CNTs, Graphene or Carbon Black. Our Identifier system is also used to monitor respirable crystalline silica in construction & mining industries and other industries where toxic materials are produced and handled.

The monitoring awareness among the CNT users is clearly the highest. The fibrous nature of the material and early toxicity studies certainly alerted everyone in the industry.

5. We’ve already mentioned a few times in Nanos’ posts how challenging it is to detect nanoforms in the environment. Tell us what the biggest challenge is in monitoring a graphene emission in the air, opposed to another carbon emission.

Raman spectroscopy has the advantage of being very selective to the material of interest. This can also be a disadvantage when the customer’s production process is not stable, meaning many different forms of a material can be present. To address that issue, we have to tune our software to be able to consider the spectral information of the deviating materials as far as possible.

6. In our perception, the nanoEHS area has advanced remarkably in Europe in the last few years, with the publication of new amendments in Reach regulations specific for nanomaterials, for example. What is your perception of the nanoEHS area in this period and how has this impacted the work of Stat Peel?

On one hand it has brought the topic of “nano” with all its advantages and disadvantages to the forefront of anyone involved or considering getting involved with such materials. On the other hand, the negative perception and regulatory burden slowed the implementation of novel materials in many industries in Europe. Therefore, Stat Peel has to be active in overseas markets where material adoption is further progressed.

7. What is the greatest benefit or advantage of companies that work with graphene or other nanomaterials that invest in the search for monitoring solutions?

It is just good business practice on many levels. For example, monitoring provides the necessary data to avoid legal issues which could endanger the survival of the company. The collected data can help to lower insurance premiums, having a direct positive financial impact. Also being able to present data to employees that their work environment is safe is a valuable tool to attract and retain talent.

Referências

- https://www.statista.com/statistics/1040399/global-market-capitalization-leading-graphene-companies/

- OSHA – Occupational Safety and Health Administration. Info sheet: Manufactured nanomaterials in the workplace, 2018. https://osha.europa.eu/en/publications/info-sheet-manufactured-nanomaterials-workplace/view

- WHO. WORLD HEALTH ORGANIZATION. Guidelines on protecting workers from potential risks on protecting workers of manufactured nanomaterials, 82 p., 2017.

- LENZ, G.; VIANA, C.; DOMINGUES, D.; VIEIRA, F. Risk assessment and health, safety, and environmental management of carbon nanomaterials. 10.5772/intechopen.85485, 2019. https://www.intechopen.com/books/nanomaterials-toxicity-human-health-and-environment/risk-assessment-and-health-safety-and-environmental-management-of-carbon-nanomaterials#B66

- ECHA – European Chemicals Agency. Guidance on information requirements and chemical safety assessment Appendix R14-4 Recommendations for nanomaterials applicable to Chapter R.14 Occupational exposure estimation. https://echa.europa.eu/documents/10162/13643/appendix_r14_05-2012_en.pdf/7b2ee1ff-3dc7-4eab-bdc8-6afd8ddf5c8d

- DOMINGUES, D. S. Desenvolvimento e avaliação de uma metodologia para caracterização ambiental e laboral de grefeno e grafite em suspensão no ar gerados durante o processamento de esfoliação química. Dissertação (Mestrado em Ciências e Tecnologia das Radiações, Minerais e Materiais) – Centro de Desenvolvimento da Tecnologia Nuclear. Minas Gerais, p. 118, 2019.

- VIANA, C. O.; DOMINGUES, D. S. et al. Graphene detection in air: a proposal based on thermogravimetric behaviour. 2019 J. Phys.: Conf. Ser. 1323 012006. https://iopscience.iop.org/article/10.1088/1742-6596/1323/1/012006